P0092 – Fuel Pressure Regulator Control Circuit High

POSTED IN pcodes

Welcome to our article on the P0092 trouble code, which refers to a high voltage signal detected in the control circuit of the electronic fuel pressure regulator. If your vehicle’s engine control module (ECM) detects this circuit malfunction, it may store a diagnostic trouble code (DTC) P0092 and illuminate the malfunction indicator lamp (MIL).

The fuel pressure regulator plays a crucial role in maintaining the fuel system’s proper functioning by controlling the fuel pressure. When the voltage in the control circuit is increased, the regulator valve opens, leading to high fuel pressure. However, if the actual control circuit voltage is lower than expected, it can result in the P0092 code.

This code can cause various engine performance issues, including engine misfire, reduced fuel efficiency, delayed startup, and black smoke from the exhaust system. It is important to address the P0092 code promptly to prevent potential damage to your engine and ensure optimal fuel regulation.

In this article, we will provide you with a technical description of the P0092 code, discuss its severity and symptoms, explore common causes, and guide you through the troubleshooting steps and repair process.

Stay tuned to gain a deeper understanding of this diagnostic trouble code and learn how to effectively resolve engine performance issues related to the fuel pressure regulator control circuit.

Buy tested tuning file for Adblue / EGR / DPF / Adblue off now!

Key Takeaways:

- The P0092 code indicates a high voltage signal in the control circuit of the fuel pressure regulator.

- This code can cause engine misfire, reduced fuel efficiency, delayed startup, and black smoke from the exhaust system.

- Common causes include a faulty fuel pressure sensor, defective fuel pressure regulator, shorted or open wiring in the control circuit, or a problem with the ECM.

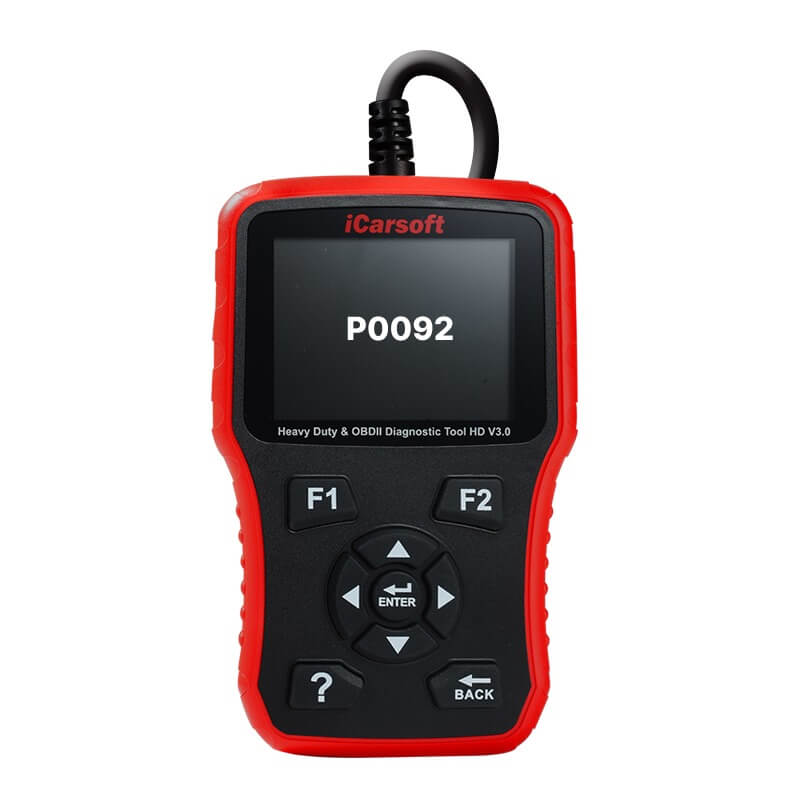

- Diagnosing and repairing this code requires the use of a diagnostic scanner, a digital volt/ohmmeter, and a fuel pressure gauge.

- Promptly addressing the P0092 code is crucial to prevent further engine damage and ensure optimal fuel efficiency.

Diagnostic Trouble Code P0092 – Technical Description

When it comes to diagnosing engine issues, understanding technical descriptions and diagnostic trouble codes (DTCs) is essential. A common DTC that you may encounter is P0092 – Fuel Pressure Regulator Control Circuit High. Let’s explore the technical aspects of this diagnostic trouble code and gain a deeper understanding of its implications.

The P0092 code is a generic powertrain code that applies to vehicles equipped with OBD-II systems. It indicates that the powertrain control module (PCM) has detected a high voltage signal from the control circuit of the electronic fuel pressure regulator. The PCM plays a crucial role in regulating the fuel pressure to ensure optimal engine performance.

The electronic fuel pressure regulator, controlled by the PCM, uses a servo motor to adjust the position of a valve, thereby controlling the fuel pressure. The PCM continuously monitors the fuel pressure sensor and adjusts the voltage to the fuel pressure regulator as needed. If the actual control circuit voltage is lower than expected, a P0092 code is logged.

“The P0092 code indicates a high voltage signal in the control circuit of the fuel pressure regulator, which can disrupt the fuel pressure regulation system.”

It is important to address the P0092 code promptly as it can lead to engine misfires, reduced fuel efficiency, delayed startup, and even black smoke from the exhaust system. By understanding the technical description of this code, you can better grasp its significance and take appropriate diagnostic and repair steps.

Diagnostic Steps:

- Inspect the wiring and connectors in the control circuit of the fuel pressure regulator.

- Use a diagnostic scanner to retrieve stored codes and freeze frame data.

- Check for proper voltage and ground at the fuel pressure regulator.

- Test the fuel system pressure using a fuel pressure gauge.

- Utilize a digital volt/ohmmeter (DVOM) to test the electronic fuel pressure regulator and control circuits.

By following these diagnostic steps and utilizing the necessary tools, you can pinpoint the underlying cause of the P0092 code and make the appropriate repairs. It is crucial to exercise caution when working with high-pressure fuel systems to avoid any accidents or injuries.

Now that you have a better understanding of the technical description of the P0092 code, let’s explore the symptoms, severity, common causes, and detailed diagnostic and repair procedures in the subsequent sections of this article.

Symptoms and Severity of P0092 Code

Experiencing engine issues and concerned about a potential P0092 code? Recognizing the symptoms is crucial to address the severity of the problem. Here are some key indicators to watch out for:

1. Engine Misfire:

If your engine is misfiring, it could be a sign of a P0092 code. This occurs when the fuel pressure regulator control circuit has a high voltage, affecting the engine’s performance and causing it to run unevenly. Don’t ignore this warning sign as it can lead to further damage.

2. Reduced Fuel Efficiency:

If you notice a significant decrease in your vehicle’s fuel efficiency, it could be due to a P0092 code. The high voltage in the fuel pressure regulator control circuit can disrupt the proper regulation of fuel, leading to excessive fuel consumption. Addressing this issue promptly can help you save on fuel costs in the long run.

3. Delayed Startup:

Experiencing difficulties starting your engine, especially when it’s cold? This delayed startup could be attributed to a P0092 code. The high voltage in the control circuit hinders the proper fuel pressure regulation, which can cause challenges in starting the engine, particularly in cooler temperatures.

4. Black Smoke from the Exhaust System:

If you’ve noticed black smoke coming from your exhaust system, it could be a result of a P0092 code. The high voltage in the control circuit can lead to an improper air-fuel mixture, causing excessive fuel to burn and generate black smoke. This symptom should not be ignored, as it indicates potential internal engine and catalytic converter damage.

Considering the symptoms mentioned above, it’s evident that a P0092 code should be treated as a severe issue. Ignoring the symptoms can lead to further engine damage and decreased fuel efficiency.

Don’t let these symptoms go unnoticed. Take the necessary steps to diagnose and resolve the P0092 code to ensure optimal engine performance and fuel efficiency.

Common Causes of P0092 Code

When diagnosing and troubleshooting a P0092 code, it is important to consider the common causes that can lead to this issue. These causes include:

- Faulty Fuel Pressure Sensor: A malfunctioning or defective fuel pressure sensor can send incorrect signals to the engine control module, leading to high fuel pressure readings and triggering the P0092 code.

- Defective Fuel Pressure Regulator: If the fuel pressure regulator fails to regulate the fuel pressure properly, it can result in high fuel pressure levels, causing the P0092 code to be logged.

- Shorted or Open Wiring and Connectors: Shorted or open wiring in the control circuit can disrupt the proper functioning of the fuel pressure regulator, leading to a high voltage signal and the P0092 code.

- PCM Programming Error: In some cases, a programming error in the powertrain control module (PCM) can cause it to incorrectly interpret the voltage signal from the fuel pressure regulator control circuit, resulting in the P0092 code.

It is crucial to inspect these common causes thoroughly during the diagnostic process to identify the root cause of the P0092 code accurately. By addressing these issues, you can resolve the fuel pressure regulation problem and prevent further engine performance issues.

Diagnostic and Repair Procedures for P0092 Code

Diagnosing a P0092 code requires the use of a diagnostic scanner, a digital volt/ohmmeter, and a fuel pressure gauge. The diagnostic process involves the following steps:

- Visually inspect the wiring and connectors: Check for any signs of damage, loose connections, or corrosion that may be affecting the fuel pressure regulator control circuit.

- Retrieve stored codes and freeze frame data: Use a diagnostic scanner to retrieve any additional codes stored in the engine control module (ECM). Freeze frame data can also provide valuable information regarding the conditions that led to the code being triggered.

- Check voltage and ground at the fuel pressure regulator: Measure the voltage and ground connections at the fuel pressure regulator using a digital volt/ohmmeter. Ensure that the voltage levels are within the manufacturer’s specified range.

- Test fuel system pressure: Connect a fuel pressure gauge to the fuel rail or fuel line and measure the pressure while the engine is running. Compare the measured pressure to the manufacturer’s specifications.

- Test the electronic fuel pressure regulator and control circuits: If necessary, use the digital volt/ohmmeter to test the electronic fuel pressure regulator and control circuits. Follow the manufacturer’s guidelines and specifications for testing procedures.

During the diagnostic process, it is crucial to exercise caution when working with high-pressure fuel systems to prevent any potential accidents or injuries.

Example Fuel Pressure Specifications

| Engine Condition | Fuel Pressure (psi) |

|---|---|

| Engine off | 40-45 psi |

| Idle | 35-45 psi |

| Wide-open throttle | 55-62 psi |

Replacement Parts for P0092 Code

To fix a P0092 code, you may need to replace certain components in your vehicle’s fuel system. Below are the possible replacement parts that can help resolve the issue:

| Replacement Part | Description |

|---|---|

| Fuel Pump | A device that delivers fuel from the fuel tank to the engine via the fuel injection system. |

| Fuel Pressure Sensor | A sensor that measures the pressure of the fuel in the fuel rail, allowing the engine control unit (ECU) to adjust the fuel delivery. |

| Fuel Pressure Regulator | A valve that controls the fuel pressure in the fuel rail, ensuring proper fuel delivery to the engine. |

| Fuel Injection System | A system that atomizes and delivers controlled amounts of fuel into the engine cylinders for combustion. |

| Fuel Filters | Filters that remove impurities and contaminants from the fuel before it reaches the fuel injectors and engine. |

| Diagnostic Tools | Tools such as a diagnostic scanner or a digital volt/ohmmeter that help diagnose and troubleshoot the P0092 code. |

| Engine Control Unit (ECU) | The ECU, also known as the engine control module, is responsible for monitoring various systems in the vehicle, including fuel delivery and pressure regulation. |

By replacing these parts, you can ensure proper fuel pressure and improve the overall performance of your vehicle.

Easy Diagnosis of P0092 Code

Diagnosing the P0092 – Fuel Pressure Regulator Control Circuit High code can be a straightforward process if you follow the right steps. The key components to focus on during the diagnosis include the electronic fuel pressure regulator, fuel rail pressure sensor, PCM, and fuel pressure regulation system.

Diagnostic Steps:

- Inspect the wiring and connectors: Start by visually examining the wiring and connectors related to the fuel pressure regulator and control circuit. Look for any signs of damage, corrosion, or loose connections that could affect the circuit’s performance.

- Repair or replace damaged components: If any issues are detected during the inspection, repair or replace the damaged or faulty components. This may involve repairing wiring, replacing connectors, or replacing the fuel pressure regulator or sensor, depending on the specific problem.

- Retest the system: After addressing any wiring or component issues, it’s crucial to retest the system to ensure that the P0092 code does not reappear. Use a diagnostic scanner to clear any stored codes and perform a functionality check to verify that the fuel pressure regulation is within the expected range.

By following these diagnostic steps, you can effectively identify and address the underlying cause of the P0092 code, restoring proper fuel pressure regulation and resolving any associated engine performance issues.

| Potential Issues to Investigate |

|---|

| Electronic Fuel Pressure Regulator |

| Fuel Rail Pressure Sensor |

| Powertrain Control Module (PCM) |

| Fuel Pressure Regulation System |

Conclusion

In conclusion, the P0092 code signifies a high voltage signal in the control circuit of the fuel pressure regulator, leading to various engine performance issues such as misfires, reduced fuel efficiency, delayed startup, and black smoke from the exhaust system. To fix this issue, it is crucial to diagnose the problem using diagnostic tools and replace any faulty components.

By promptly addressing the P0092 code, you can prevent further damage to your engine and ensure optimal fuel efficiency. Remember to seek professional assistance or consult your vehicle’s manufacturer for specific troubleshooting steps and repair procedures.

Don’t ignore the significance of a well-functioning fuel pressure regulator control circuit. Taking appropriate action to diagnose and fix the P0092 code will help restore your engine’s performance and overall functionality.

FAQ

What is the P0092 trouble code?

The P0092 trouble code refers to a high voltage signal detected in the control circuit of the electronic fuel pressure regulator. It is a diagnostic trouble code that indicates a malfunction in the fuel pressure regulation system.

What are the symptoms of a P0092 code?

The symptoms of a P0092 code may include engine misfire, reduced fuel efficiency, delayed startup when the engine is cool, and black smoke from the exhaust system.

What are the common causes of a P0092 code?

Common causes of a P0092 code include a faulty fuel pressure sensor, defective fuel pressure regulator, shorted or open wiring and/or connectors in the control circuit, and a PCM programming error.

How is a P0092 code diagnosed and repaired?

Diagnosing a P0092 code requires the use of a diagnostic scanner, a digital volt/ohmmeter, and a fuel pressure gauge. The diagnostic process involves visually inspecting the wiring and connectors, retrieving stored codes and freeze frame data, checking for correct voltage and ground at the fuel pressure regulator, and testing the fuel system pressure. The electronic fuel pressure regulator and control circuits may also need to be tested using the DVOM.

What parts may need to be replaced to fix a P0092 code?

Possible replacement parts for a P0092 code include the fuel pump, fuel pressure sensor, fuel pressure regulator, fuel injection system, fuel filters, diagnostic tools, and engine control unit. These parts play a crucial role in maintaining fuel pressure and ensuring proper fuel delivery.